Backflow preventers, crucial for industrial facilities, guard against water contamination. Certified commercial installations in Fayetteville ensure compliance with local codes using specialized RPZ (Reduced Pressure Zone) backflow preventers tailored to industrial needs. Regular maintenance is vital for safety, environmental compliance, and system integrity. Choosing the right RPZ setup, guided by experts, offers robust protection, adheres to regulations, and ensures efficient operation. This comprehensive guide emphasizes site-specific requirements, structured installation, testing, and the challenges of inline preventers in industrial applications, highlighting the importance of professional, authorized installation for Fayetteville businesses.

In the realm of industrial safety, understanding backflow preventers is paramount. These devices play a crucial role in protecting systems from contamination and ensuring the quality of fluids. For businesses in Fayetteville, backflow preventer installation is not just a maintenance task but a legal requirement. This article explores the importance of certified commercial installation, offers insights on choosing the ideal RPZ backflow preventer, provides a step-by-step setup guide, and delves into the benefits and challenges of inline backflow preventer installation, while adhering to local regulations.

- Understanding Backflow Preventers: Their Role in Industrial Safety

- The Importance of Certified Commercial Installation

- Choosing the Right RPZ Backflow Preventer for Your Site

- Step-by-Step Guide to Efficient Backflow Preventer Setup

- Benefits and Potential Challenges of Inline Installation

- Local Regulations and Compliance for Fayetteville Businesses

Understanding Backflow Preventers: Their Role in Industrial Safety

Backflow preventers play a vital role in maintaining safety and hygiene standards at industrial facilities. These devices are designed to stop backflow, or the reverse flow of water or other liquids, which can carry harmful contaminants into drinking water sources or clean water supplies used for processing. In industrial settings, where various chemicals and potentially toxic substances are handled, having a reliable backflow prevention system is crucial. A certified commercial backflow preventer installation in Fayetteville ensures that these critical components are set up correctly, adhering to local codes and regulations.

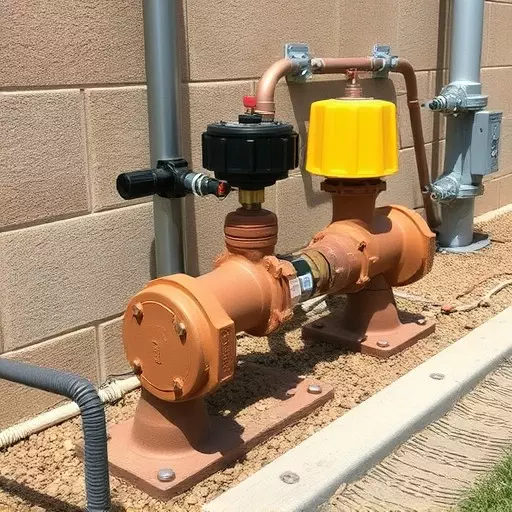

Industrial sites often require specialized backflow preventers like RPZ (Reduced Pressure Zone) backflow preventers. These devices are engineered to protect water supplies from hazardous substances that may be used or produced on-site. Proper installation and regular maintenance of backflow preventers are essential to guarantee the safety and integrity of the industrial water system, preventing potential health hazards and ensuring compliance with environmental regulations.

The Importance of Certified Commercial Installation

When it comes to inline backflow preventer installation for industrial applications in Fayetteville, certified commercial installation is paramount. Not only does it ensure compliance with local regulations, but it also guarantees the safety and reliability of your water supply system. Professional installers who specialize in RPZ (Reduced Pressure Zone) backflow preventer setup possess the expertise to navigate the complex requirements of industrial sites, where precise configuration and robust protection against contamination are non-negotiable.

A certified commercial backflow preventer installation service offers peace of mind by minimizing the risk of waterborne contaminants entering your system. These professionals adhere to strict industry standards and guidelines, ensuring that every component is correctly sized, installed, and tested for optimal performance. This meticulous approach not only protects sensitive industrial processes but also complies with regulatory bodies, avoiding potential fines and legal issues associated with non-compliance.

Choosing the Right RPZ Backflow Preventer for Your Site

When selecting an RPZ (Redundant Pressure Zone) backflow preventer for your industrial site in Fayetteville, it’s crucial to consider several factors. First and foremost, understand your facility’s specific needs and pressure requirements. Different industries have varying demands, so a certified commercial backflow preventer installation expert can guide you in choosing the most suitable RPZ model. These experts ensure that the selected backflow preventer is designed to handle your site’s unique challenges, meeting all necessary regulations for safe water supply.

The right RPZ backflow preventer setup offers robust protection against contamination and ensures compliance with local plumbing codes. It’s essential to opt for a reputable brand known for its quality and reliability in industrial settings. With the help of these professionals, you can find a backflow preventer tailored to your site, ensuring efficient operation, minimal maintenance, and peace of mind.

Step-by-Step Guide to Efficient Backflow Preventer Setup

Step-by-Step Guide to Efficient Backflow Preventer Setup

For a certified commercial backflow preventer installation in Fayetteville, following a structured setup process is crucial to ensure optimal performance and compliance with regulations. The first step involves assessing the specific needs of the industrial site, including identifying potential hazards and flow patterns. This evaluation guides the selection of the appropriate type of backflow preventer, such as an RPZ (Reduced Pressure Zone) device, designed for robust industrial applications.

Once the right backflow preventer is chosen, the installation process begins with careful preparation. This includes isolating the system, ensuring proper drainage, and verifying that all necessary components are on hand. The actual setup entails connecting the preventer to the water supply lines while adhering to strict guidelines for pressure ratings and flow directions. Regular testing post-installation is vital to guarantee the backflow preventer’s effectiveness in safeguarding the industrial site’s water supply from contamination.

Benefits and Potential Challenges of Inline Installation

The decision to implement inline backflow preventer installations in Fayetteville for industrial applications offers several significant advantages. One of the primary benefits is the enhanced safety it provides by stopping contaminated water from flowing back into potable water systems, thus mitigating potential health risks and ensuring water quality. This setup also streamlines maintenance processes as compared to traditional backflow preventer models, as issues can be resolved without requiring complete system shutdowns, minimizing downtime for industrial operations.

However, there are potential challenges associated with inline installation. These include the need for precise engineering and customization to fit specific industrial site requirements, ensuring compatibility with existing plumbing systems. Additionally, while online installations offer efficiency in maintenance, they may require more complex troubleshooting techniques when issues arise compared to traditional models. Proper execution of RPZ backflow preventer setup for industrial sites necessitates the expertise of certified commercial backflow preventer installation professionals who can navigate these challenges effectively.

Local Regulations and Compliance for Fayetteville Businesses

In Fayetteville, businesses operating industrial applications must adhere to stringent local regulations regarding backflow preventer installation. These regulations are designed to maintain water quality and ensure the safety of both residents and commercial operations. For establishments requiring certified commercial backflow preventer installation, it’s crucial to understand and comply with these standards, especially when dealing with high-risk industrial sites.

The RPZ (Reduced Pressure Zone) backflow preventer setup is a common requirement for such facilities. This specialized equipment plays a vital role in preventing backflow of contaminated water into the main supply, thereby mitigating potential health risks. Professional installation by authorized technicians is essential to guarantee compliance and the effective operation of these critical safety mechanisms.