Cross-connections and backflow prevention are critical for maintaining water quality in Fayetteville and surrounding areas. Certified professionals install RPZ backflow preventers to safeguard potable water systems from hazardous substance backflow, adhering to local regulations and industry standards. Regular testing and maintenance ensure these systems remain effective, preventing contamination from industrial sites handling chemicals or high-risk processes.

“In the realm of water infrastructure, ensuring the integrity of the supply chain is paramount. Compliance-focused cross-connection backflow prevention systems play a vital role in safeguarding drinking water sources from potential contaminants. This article delves into the essential aspects of these systems, offering a comprehensive guide for businesses in Fayetteville.

We explore ‘Understanding Cross-Connection and Backflow Prevention,’ emphasizing the critical role of certified professionals in installing commercial backflow preventers. Furthermore, we highlight RPZ backflow preventers as game-changers for industrial sites, ensuring safe water practices.”

- Understanding Cross-Connection and Backflow Prevention: A Brief Overview

- The Role of Certified Professionals in Backflow Preventer Installation

- RPZ Backflow Preventers: Ideal Solutions for Industrial Sites

Understanding Cross-Connection and Backflow Prevention: A Brief Overview

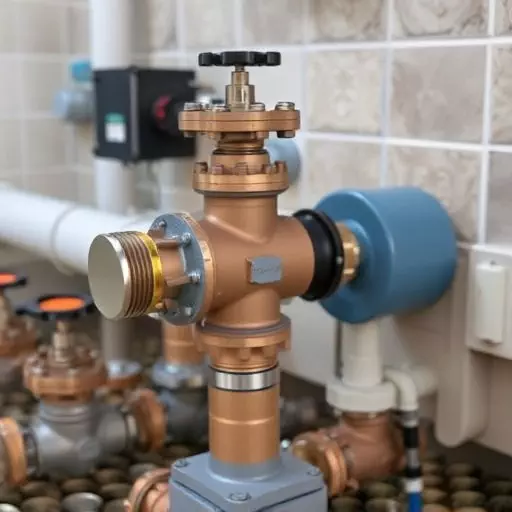

Cross-connection and backflow prevention are critical concepts in maintaining water quality and ensuring safe drinking water distribution. A cross-connection occurs when a potential path for contaminated water to enter the potable water supply is established, allowing backflow from non-potable sources into the main water system. This can happen due to various reasons, such as incorrect plumbing configurations or faulty equipment. Backflow preventers, like RPZ (Reduced Pressure Zone) devices, are designed to protect water systems by stopping this backflow and preventing any contamination.

In Fayetteville and beyond, certified commercial backflow preventer installation is essential for industrial sites and other high-risk areas. These specialized professionals ensure that the correct type of backflow preventer, such as an RPZ backflow preventer setup, is installed according to local regulations and industry standards. Regular testing and maintenance of these systems are also crucial to guarantee their ongoing effectiveness in safeguarding water supplies from potential hazards.

The Role of Certified Professionals in Backflow Preventer Installation

In the context of backflow preventer installation in Fayetteville, certified professionals play a pivotal role in ensuring the effectiveness and safety of these critical systems. With stringent regulations governing water quality and distribution, only qualified experts can handle the complex task of installing and maintaining backflow preventers. These professionals are equipped with the knowledge and skills to navigate the intricacies of various backflow prevention devices, such as RPZ (Reduced Pressure Zone) backflow preventers commonly used in industrial sites. Their expertise is essential for proper setup, testing, and ongoing maintenance, ensuring these systems reliably protect water supplies from potential contamination.

When it comes to commercial backflow preventer installation, certification is not just a formality; it guarantees that the process adheres to industry standards and local regulations. Certified technicians understand the nuances of different water systems and can identify potential risks specific to each site. They employ best practices during installation, including thorough testing and documentation, to guarantee the longevity and performance of backflow preventers. This expertise is particularly vital in industrial settings where RPZ backflow preventers are crucial for maintaining water quality and preventing hazardous substance backflow.

RPZ Backflow Preventers: Ideal Solutions for Industrial Sites

In industrial settings where maintaining water quality is paramount, RPZ (Reducing Pressure Zone) Backflow Preventers stand as ideal solutions. These advanced devices are designed to safeguard potable water systems from contamination by preventing backflow of potentially hazardous fluids or gases. The certified commercial backflow preventer installation process ensures that these robust mechanisms are correctly set up, adhering to stringent industry standards and local regulations, such as those often enforced in areas like Fayetteville.

The RPZ Backflow Preventer setup offers a comprehensive defense against cross-connection hazards. By maintaining positive pressure in the main water supply line, it prevents any reversal of flow, thus blocking contaminated water from entering the main system. This is particularly crucial for industrial sites where various chemicals or processes might pose risks to the broader water distribution network. Effective backflow preventer installation and maintenance are key to preserving the integrity of water systems and ensuring the safety of communities and businesses alike.